GSC

Compact soundproofed granulator

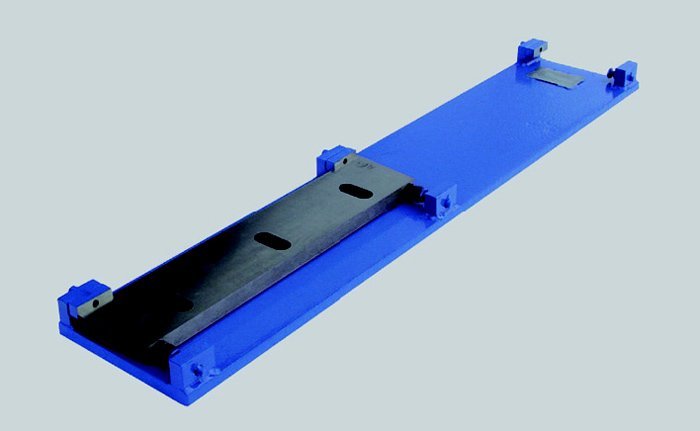

- Knives are adjusted outside of the machine

- Compact design

- Different rotor types available

- Soundproofed housing

- Aggressive tangential infeed

GSC - Compact Soundproofed Granulator

Rotor and stator knives are pre-set outside the machine prior to installation in a supplied fixture. This makes awkward adjustment inside the machine unnecessary.

The GSC granulators are available with different rotor options to fit different applications, all rotors feature the V-cut technology creating a high quality regrind.

To minimize the needed floor space and make the machine easy to move, machine controls and electrical cabinet are integrated into the machines soundproof housing.

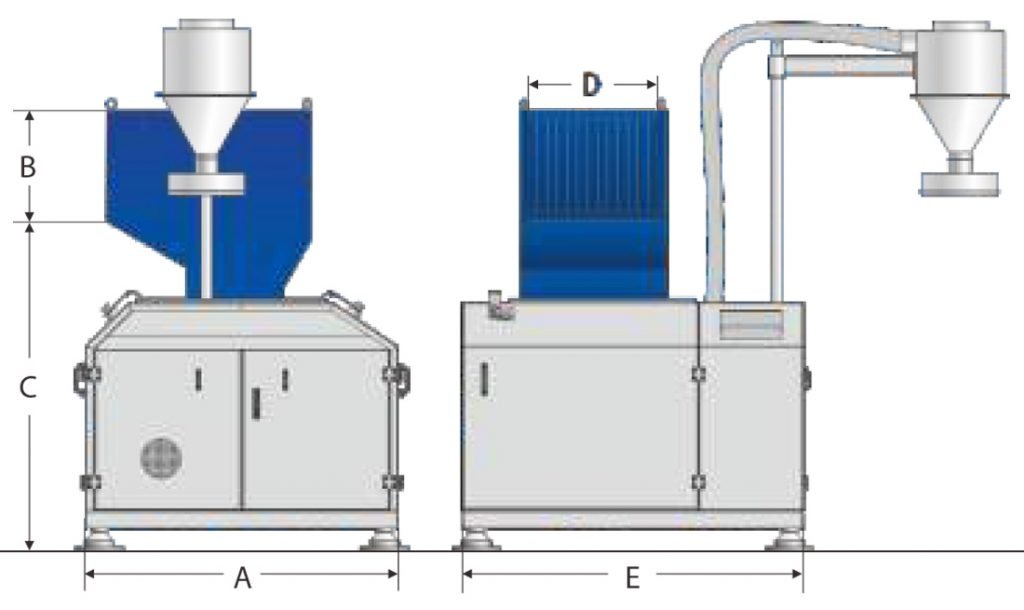

GSC Model Range

GSC 300

General Description

The GSC compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation.

Different rotor designs are available in widths ranging from 300 mm to 1400 mm with a diameter of 300 mm.

The completely welded cutting chamber in conjunction with the “V” type rotor design ensures dependability in operation and universal application use.

While it delivers excellent sound proofing capabilities, it still offers easy and quick access to the cutting chamber during rotor and stator knife changes, servicing or screen changes.

The sound dampening material used in these machines is based on the latest technological research.

Applications

The cutting geometry of the GSC series allows even voluminous materials to be ground.

The complete GSC series line achieves a high quality regrind independent of the material type or form such as injection moulded parts,blow moulded parts, profiles, sheets, film, etc.

The 300 series GSC machines are mainly used in inline operations for processing of rejected products, or runners and sprues.

The small footprint and easy movability make the machines very easy to place in existing operations.

Specifications

| Typ | 300/300 | 300/600 | 300/1000 |

|---|---|---|---|

| Rotor diameter (mm) | 300 | 300 | 300 |

| Rotor width (mm) | 300 | 600 | 1000 |

| Drive capacity (kW) | 7.5 | 18.5 | 18.5 |

| Rotor knifes (rows) | 3 | 3 | 3 |

| Stator blades (rows) | 2 | 2 | 2 |

| Screen size (mm) | > 6 | > 6 | > 6 |

| Effective working area (mm) | 400 x 290 | 400 x 590 | 400 x 990 |

| Weight approx. (kg) | 1200 | 1400 | 1850 |

| A (mm) | 1550 | 1550 | 1550 |

| B (mm) | 420 | 420 | 420 |

| C (mm) | 1570 | 1570 | 1570 |

| D (mm) | 300 | 590 | 990 |

| E (mm) | 1300 | 1600 | 1900 |

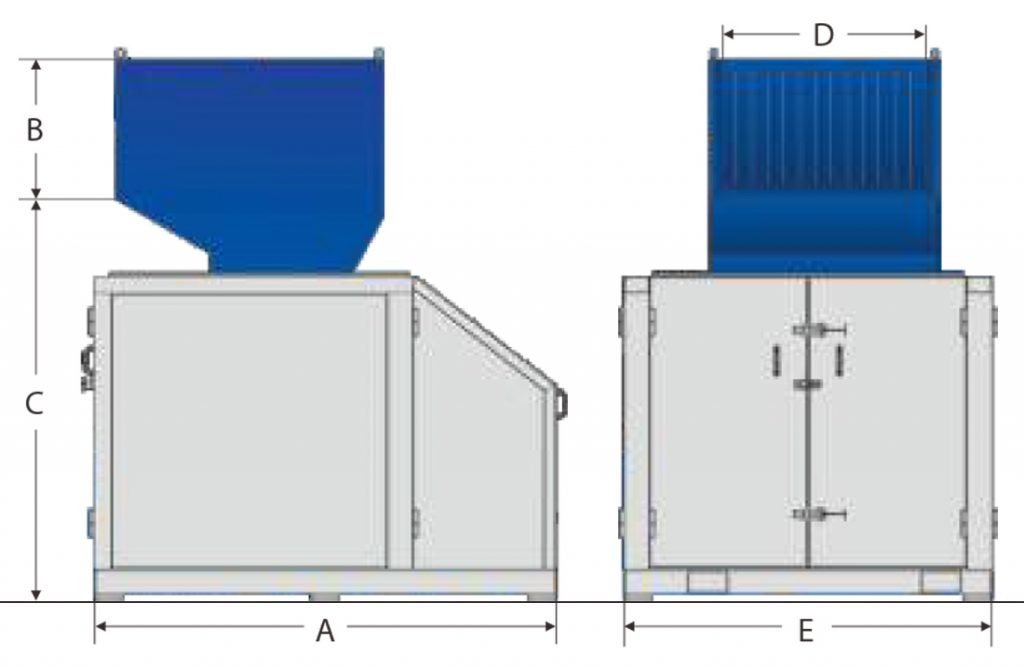

GSC 500

General description

The GSC compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation.

Different rotor designs are available in widths ranging from 500 mm to 1400 mm with a diameter of 500 mm.

The completely welded cutting chamber in conjunction with the “V” type rotor design ensures dependability in operation and universal application use.

While it delivers excellent sound proofing capabilities, it still offers easy and quick access to the cutting chamber during rotor and stator knife changes, servicing or screen changes.

The sound dampening material used in these machines is based on the latest technological research.

Applications

The cutting geometry of the GSC series allows even voluminous materials to be ground.

The complete GSC series line achieves a high quality regrind independent of the material type or form such as injection moulded parts,blow moulded parts, profiles, sheets, film, etc.

The 500 series GSC machines are mainly used in inline operations or small central granualtors for processing of medium sized hollow thin walled products, or runners and sprues.

The integrated sound proofing makes it possible to easily place the machine in existing operations.

With different rotor designs and a wide variety of options the machines can be tailored for many different applications.

Specification

| Typ | 500/500 | 500/700 | 500/1000 | 500/1400 |

|---|---|---|---|---|

| Rotor diameter (mm) | 500 | 500 | 500 | 500 |

| Rotor width (mm) | 500 | 700 | 1000 | 1400 |

| Drive capacity (kW) | 30 | 37 | 45 | 45 |

| Rotor knifes (rows) | 3 or 5 | 3 or 5 | 3 or 5 | 3 or 5 |

| Stator blades (rows) | 2 or 3 | 2 or 3 | 2 or 3 | 2 or 3 |

| Screen size (mm) | > 6 | > 6 | > 6 | > 6 |

| Effective working area (mm) | 560 x 500 | 560 x 700 | 560 x 990 | 560 x 1400 |

| Weight approx. (kg) | 2200 | 2500 | 3000 | 5500 |

| A (mm) | 1930 | 1930 | 2160 | 2160 |

| B (mm) | 580 | 580 | 580 | 580 |

| C (mm) | 1870 | 1870 | 1930 | 1930 |

| D (mm) | 515 | 715 | 985 | 1430 |

| E (mm) | 1550 | 1750 | 2100 | 2600 |

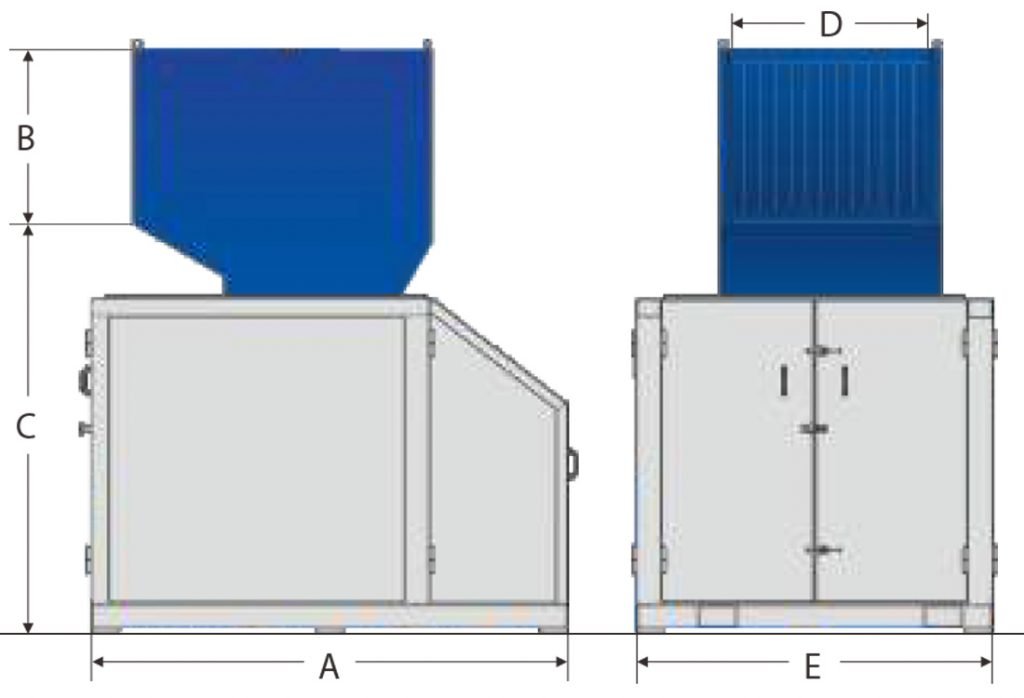

GSC 700

General Description

The GSC compact/sound proof granulators are designed with a complete sound proof enclosure resulting in an extremely quiet operation.

Different rotor designs are available in widths ranging from 700 mm to 1400 mm with a diameter of 700 mm. The completely welded cutting chamber in conjunction with the “V” type rotor design ensures dependability in operation and universal application use.

While it delivers excellent sound proofing capabilities, it still offers easy and quick access to the cutting chamber during rotor and stator knife changes, servicing or screen changes.

The sound dampening material used in these machines is based on the latest technological research.

Applications

The cutting geometry of the GSC series allows even voluminous materials to be ground.

The complete GSC series line achieves a high quality regrind independent of the material type or form such as injection moulded parts,blow moulded parts, profiles, sheets, film, etc.

The 700 series GSC machines are mainly used as central granualtors for processing of large injected or blow moulded products as well as film.

The integrated sound proofing makes it possible to easily place the machine in existing operations.

With different rotor designs and a wide variety of options the machines can be tailored for many different applications.

Specifications

| Typ | 700/700 | 700/1000 | 700/1400 |

|---|---|---|---|

| Rotor diameter (mm) | 700 | 700 | 700 |

| Rotor width (mm) | 700 | 1000 | 1400 |

| Drive capacity (kW) | 45 | 55 | 55 |

| Rotor knifes (rows) | 5 or 7 | 5 or 7 | 5 or 7 |

| Stator blades (rows) | 2 or 3 | 2 or 3 | 2 or 3 |

| Screen size (mm) | > 6 | > 6 | > 6 |

| Effective working area (mm) | 720 x 700 | 720 x 990 | 720 x 1400 |

| Weight approx. (kg) | 4200 | 5100 | 6200 |

| A (mm) | 2260 | 2260 | 2260 |

| B (mm) | 780 | 780 | 780 |

| C (mm) | 2240 | 2240 | 2240 |

| D (mm) | 715 | 915 | 1430 |

| E (mm) | 1830 | 2100 | 2600 |

More information about this model can be found on

The values of the individual machines may differ from the values in the tables due to modifications.

The correct values are available from your contact.

Do you have any questions?

Do you have questions about this machine? Can not find something?

Feel free to contact us. We’re here to help.