GSL

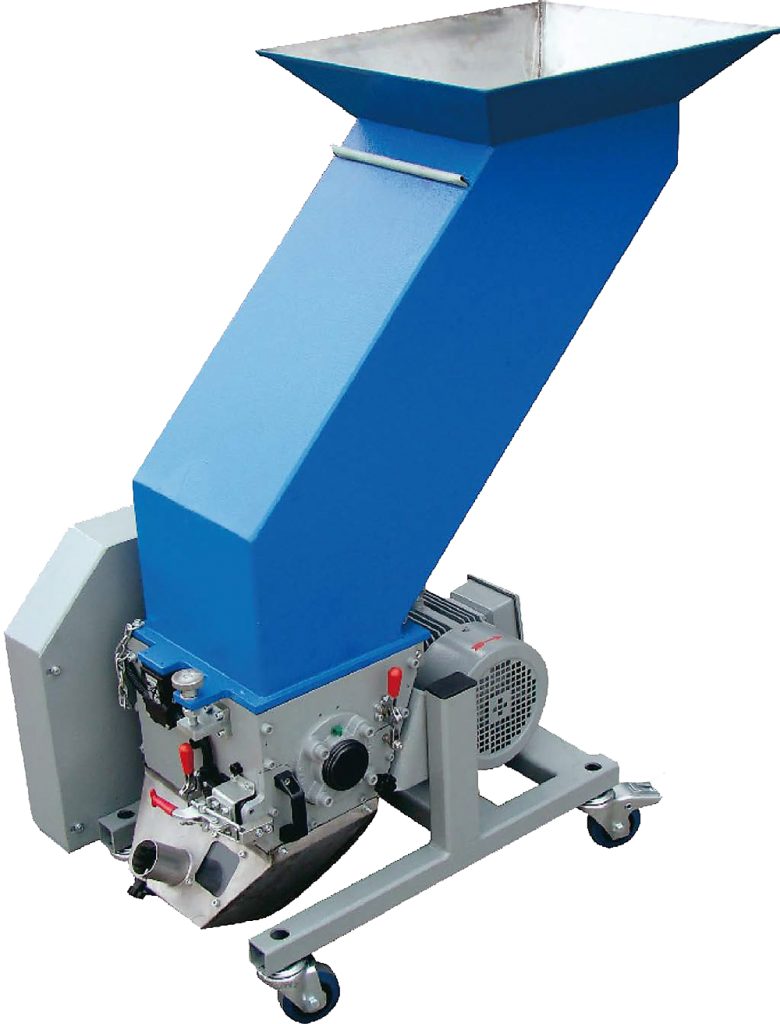

Slow speed granulator

- Direct driven staggered rotor

- Special knife design makes adjustment unnecessary

- Easy access for maintenance and cleaning

- Slow rotor speed creates less noise and dust

- Easily customizable to suit different applications

GSL - Slow Speed Granulator

The curvature of the specially profiled rotor knives ensures a constant cutting radius after re-sharpening thus maintaining the original cutting gap. Awkward knife

adjustment is no longer necessary.

Staggered rotor blades creates an individual blade cut thus increasing the cutting torque. All of the machines in this series are therefore suitable for grinding more solid

materials and thicker walled sprues.

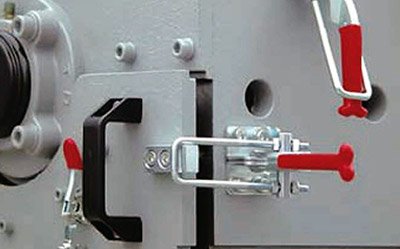

The ZERMA Quick Snap System allows the lower front plate section to be easily removed for granulator cleaning. The lower front plate section is held in position by two sturdy lever clamps.

GSL Model Range

GSL 150

General Description

Zerma introduces the new beside-the press series GSL 150/150 – GSL 150/350.

The GSL 150 slow runner series is designed for light applications in the field of injection molding.

Not only does the GSL 150 series include the standard advantages such as low noise and dust free operation, the granulator series offers a new designed rotor, stator knife and Quick-Snap-System for easy access during maintenance and cleaning.

Applications

The granulator feeding can be performed per hand or through robotics into the large dimensioned hopper which is built in layered construction.

Material is discharged through the easy accessible screen into the granulator discharge pan which includes a discharge pipe for connection of a down stream vacuum loader.

Contrary to the standard Zerma slow runners the GSL 150 series uses drive belt technology for motor/granulator power.

The drive belt technology reduces the space needed for location of the machine.

Specifications

| Typ | 150/150 | 150/250 | 150/350 |

|---|---|---|---|

| Rotor diameter (mm | 150 | 150 | 150 |

| Rotor width (mm) | 150 | 250 | 350 |

| Rotor speed (rpm) | 190 | 190 | 190 |

| Drive capacity (kW) | 1.5 | 2.2 | 3.0 |

| Rotor knifes (pcs) | 15 | 27 | 26 |

| Stator blades (rows) | 2 (4 cutting edges) | 2 (4 cutting edges) | 2 (4 cutting edges) |

| Screen size (mm | > 5 | > 5 | > 5 |

| Weight approx. (kg) | 110 | 120 | 140 |

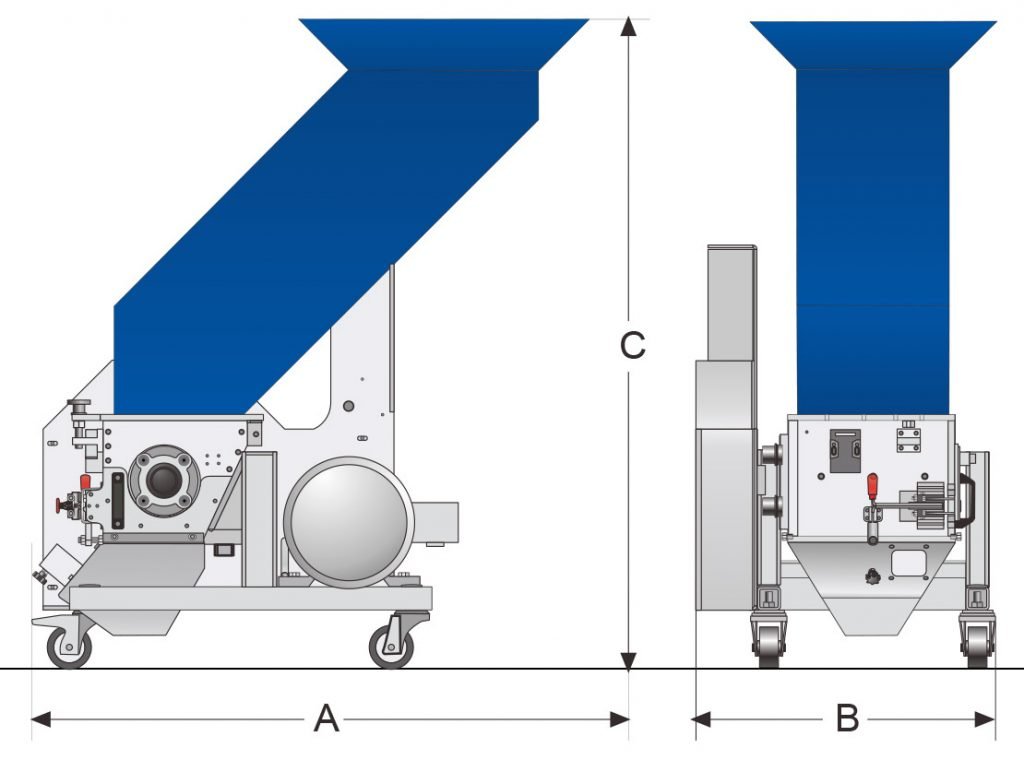

| A (mm) | 980 | 980 | 980 |

| B (mm) | 397 | 509 | 593 |

| C (mm) | 1150 | 1150 | 1150 |

GSL 180

General Description

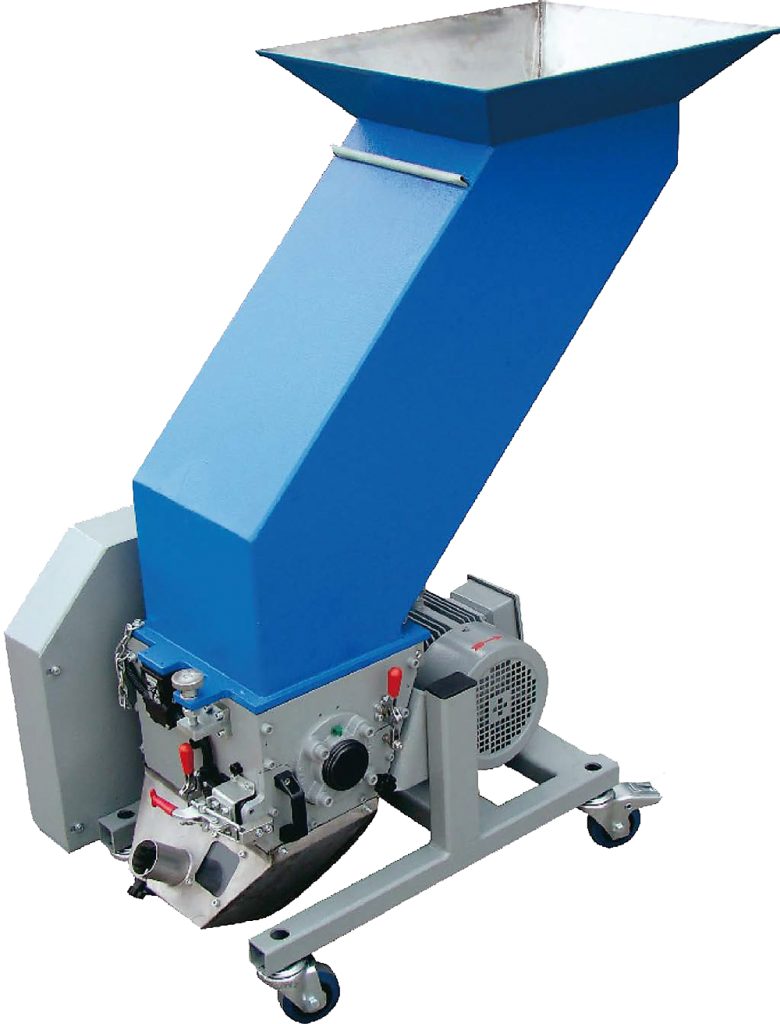

The slow speed granulators in the GSL 180 range feature a staggered 180 mm diameter rotor with widths ranging from 180 to 430 mm.

The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding.

The special design knives of the GSL series can be sharpened easily and do not need adjustment afterwards. The material is fed via a sound absorbing feed hopper that can be tailored to fit various applications and feeding ways.

Depending on the requirements the machines can be fitted with a wide variety of hoppers, they are mounted on either low or high level base frames with matching suction bins or bag filling adapters.

Quick snap fasteners and hand screws make access to the machine for cleaning and maintenance fast and easy.

Applications

The GSL slow speed granulators of the 180 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues.

The resulting granules are then immediately reintroduced into the production process. The machines can be used for rejected products in the inline recycling process as well.

Different hopper and base frame designs make it possible to integrate the machine with most types of injection molding machines and robots

Specifications

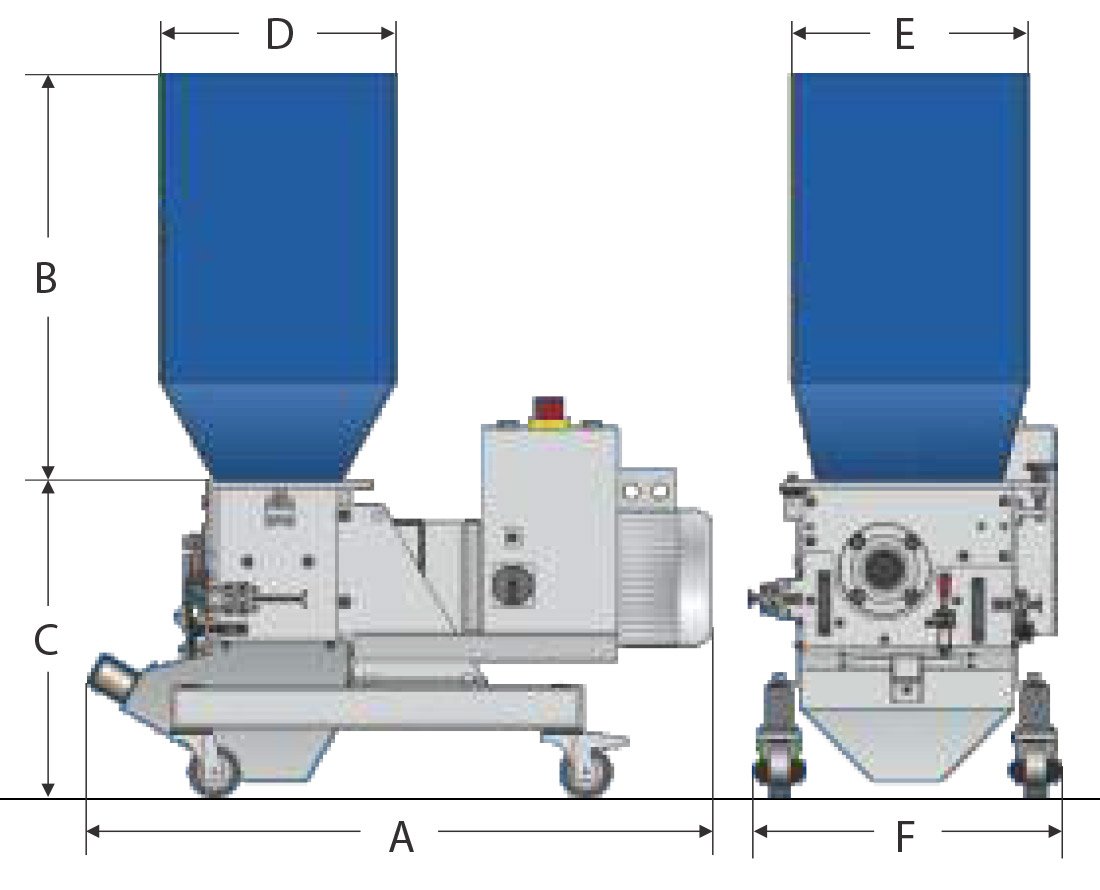

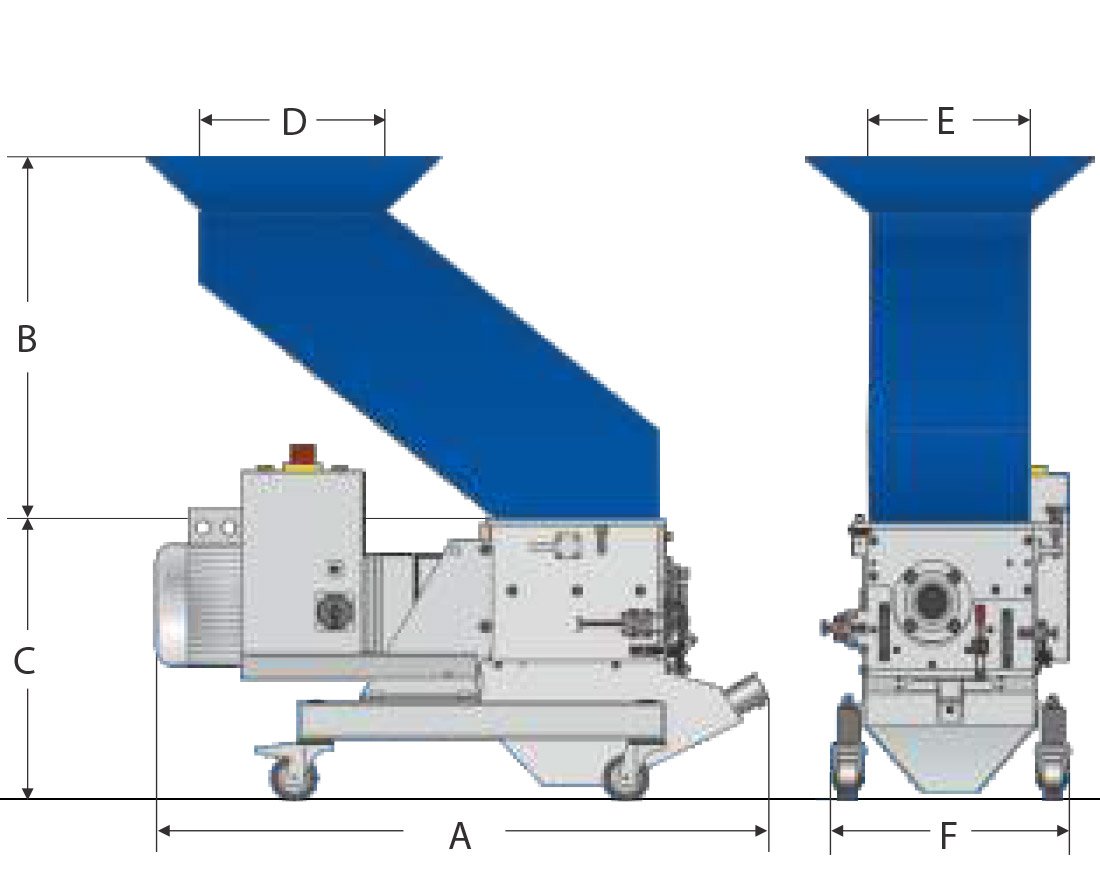

| Typ | 180/120 | 180/180 | 180/300 | 180/430 |

|---|---|---|---|---|

| Rotor diameter (mm) | 180 | 180 | 180 | 180 |

| Rotor width (mm) | 120 | 180 | 300 | 430 |

| Rotor speed (rpm) | 150 | 150 | 150 | 150 |

| Drive capacity (kW) | 2.2 | 3 | 4 | 4 |

| Rotor knifes (pcs) | 12 | 18 | 30 | 45 |

| Stator blades (rows) | 2 | 2 | 2 | 2 |

| Screen size (mm) | > 5 | > 5 | > 5 | > 5 |

| Weight approx. (kg) | 130 | 140 | 180 | 250 |

| A (mm) | 835 | 890 | 1100 | 1240 |

| B (mm) | 610 | 610 | 610 | 910 |

| C (mm) | 460 | 460 | 460 | 550 |

| D (mm) | 345 | 345 | 345 | 430 |

| E (mm) | 345 | 345 | 345 | 290 |

| F (mm) | 455 | 455 | 455 | 615 |

| Measurement bevelled hopper | ||||

| A (mm) | 835 | 895 | 1100 | 1240 |

| B (mm) | 760 | 760 | 760 | 820 |

| C (mm) | 470 | 470 | 470 | 560 |

| D (mm) | 315 | 315 | 345 | 525 |

| E (mm) | 270 | 270 | 270 | 270 |

| F (mm) | 440 | 440 | 440 | 540 |

GSL 300

General Description

The slow speed granulators in the GSL 300 range feature a staggered 300 mm diameter rotor with widths ranging from 400 to 800 mm.

The rotor is directly driven by a geared motor. The low rotor speed reduces the noise level of the machine and creates less dust while grinding.

The special design knives of the GSL series can be sharpened easily and do not need adjustment afterwards. The material is fed via a sound absorbing feed hopper that can be tailored to fit various applications and feeding ways.

Depending on the requirements the machines can be fitted with a wide variety of hoppers, they are mounted on either low or high level base frames with matching suction bins or bag filling adapters.

Quick snap fasteners and hand screws make access to the machine for cleaning and maintenance fast and easy.

Applications

The GSL slow speed granulators of the 300 series are mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues.

But they can be used as low noise central granulators for small throughput requirements as well.

The stronger design of the 300 series GSLs allow them to be used for stronger and thicker materials while offering the same advantages regarding low noise and dust as the smaller GSL machines.

All GSL models can be equipped with a built in blower system in case a vacuum loading system is not available, or to transport the ground material to bags for storage.

Specifications

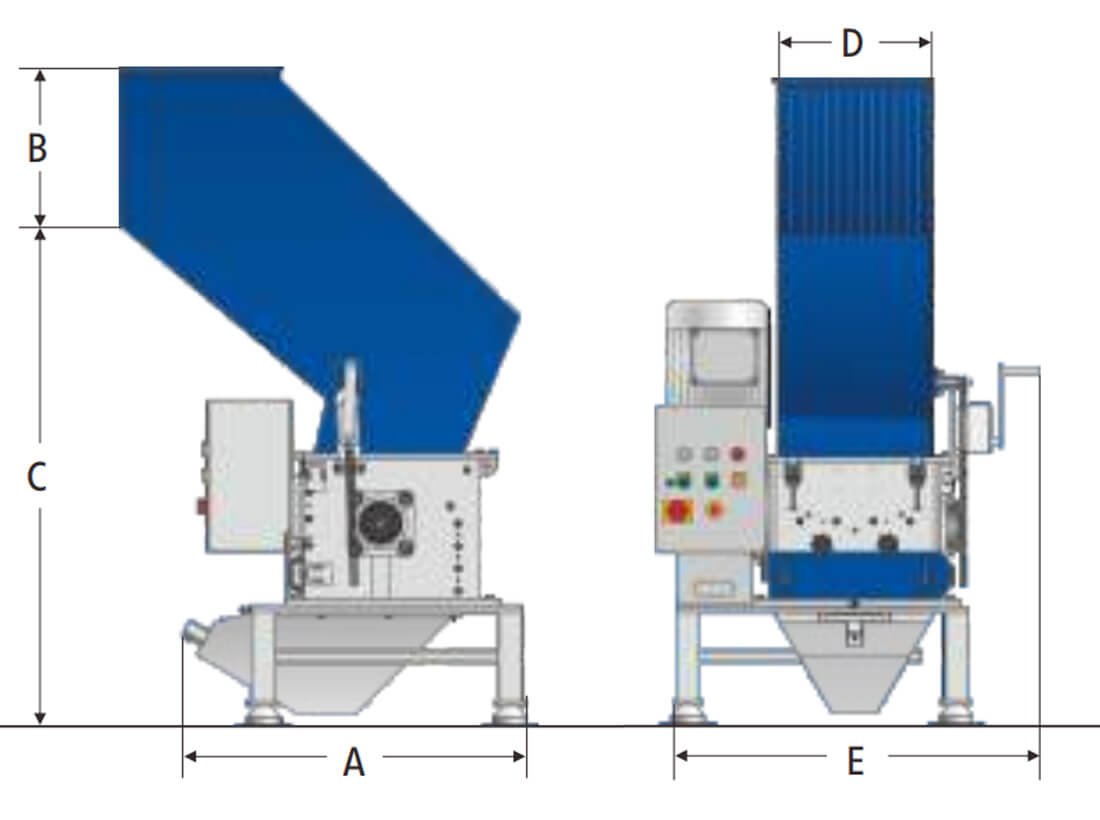

| Typ | 300/400 | 300/600 | 300/800 |

|---|---|---|---|

| Rotor diameter (mm) | 300 | 300 | 300 |

| Rotor width (mm) | 400 | 600 | 800 |

| Rotor speed (rpm) | 150 | 150 | 150 |

| Drive capacity (kW) | 7.5 | 11 | 18.5 |

| Rotor knifes (pcs) | 33 | 48 | 66 |

| Stator blades (rows) | 2 | 2 | 2 |

| Screen size (mm) | > 6 | > 6 | > 6 |

| Weight approx. (kg) | 550 | 950 | 1100 |

| A (mm) | 950 | 1125 | 820 |

| B (mm) | 400 | 400 | 400 |

| C (mm) | 1335 | 1335 | 1340 |

| D (mm) | 405 | 600 | 830 |

| E (mm) | 1035 | 1230 | 1635 |

The values of the individual machines may differ from the values in the tables due to modifications.

The correct values are available from your contact.

Do you have any questions?

Do you have questions about this machine? Can not find something?

Feel free to contact us. We’re here to help.