ZSS / ZPS

General purpose shredder

- Low speed, high torque geared drive

- Powerful hydraulic swing type pusher (ram)

- Proven well engineered design

- Smaller footprint compared to traditional horiz-

ontal pusher style shredders - Bolt-in drive shafts

- Multiple rotor designs and materials

- Two speed hydraulic system as standard

Overview

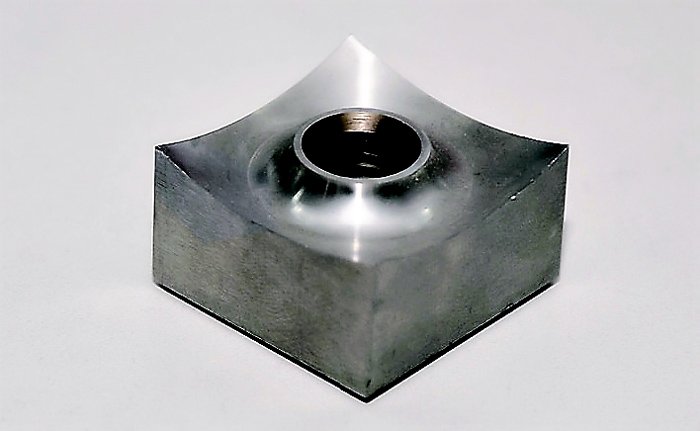

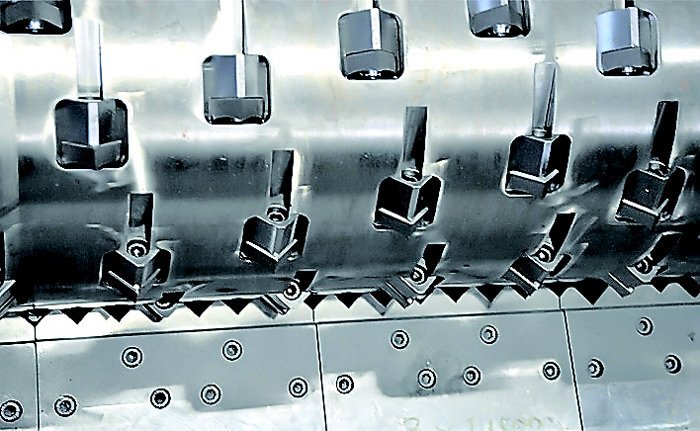

All ZERMA shredders are equipped with a large diameter flat rotor. The knives are fixed in special knife holders fitted in machined pockets. Optional weld on hard facing is available for abrasive applications.

The ZSS series shredders benefit from sturdy ram construction incorporating heavy duty guide bearings and universal couplings for reliable operation.

General Description

The ZSS shredders are single shaft shredders with a powerful two speed swing ram design eliminating the risk of blocking and wearing out of internal guide rails. The machine is very versatile and can be used for shredding of all kinds of input materials and is well suited for different industries.

The 457 mm diameter rotors ranging from 850mm to 2000 mm width are driven by either one or two oversized gearboxes. The hydraulic power pack is well integrated into the machine housing to save space and protect it from damage but is still easy to access or remove for maintenance.

The standard E rotor features the proven ZERMA knife and knife holder design, as well as outboard bearings and a hydraulically operated screen cradle.

The machines can be tailored to various applications and is offered with rotor cooling, hard facing and other wear options.

Applications

The ZSS shredders have been designed for a wide range of applications and industries such as in-house and general recycling, electronic waste and post consumer waste handling.

Input materials can be all types and forms of plastics such as lumps, pipes, film, bales, woven bags; electronic waste like cables and ICBs, paper, wood and other organic materials.

Depending on downstream requirements, the shredded material, with size defined by the fitted screen size, can be used directly or can pass to the next stage of size reduction, for example a GSH granulator.

Specifications

| Typ | 850 | 850+ | 1200 | 1500 | 2000 |

|---|---|---|---|---|---|

| Rotor diameter (mm) | 387 | 457 | 457 | 457 | 457 |

| Rotor width (mm) | 850 | 850 | 1130 | 1410 | 1970 |

| Rotor speed (rpm) | 74 | 74 | 74 | 74 | 74 |

| Drive capacity (kW) | 37 | 55 | 55 | 75 | 2 x 55 |

| Rotor knifes (pcs) | 40 / 60 | 40 / 60 | 54 / 81 | 68 / 102 | 96 / 144 |

| Stator blades (rows) | 1 | 1 | 1 | 1 | 1 |

| Ram feeder drive (kW) | 5.5 | 5.5 | 5.5 | 5.5 | 5.5 |

| Screen size (mm) | > 40 | > 40 | > 40 | > 40 | > 40 |

| Cutting chamber volume (m3) | 1.16 | 1.37 | 1.82 | 2.27 | 3.16 |

| Effective working area (mm) | 690 x 730 | 800 x 730 | 800 x 1010 | 800 x 1290 | 800 x 1850 |

| Weight approx. (kg) | 4200 | 4800 | 5500 | 6500 | 8500 |

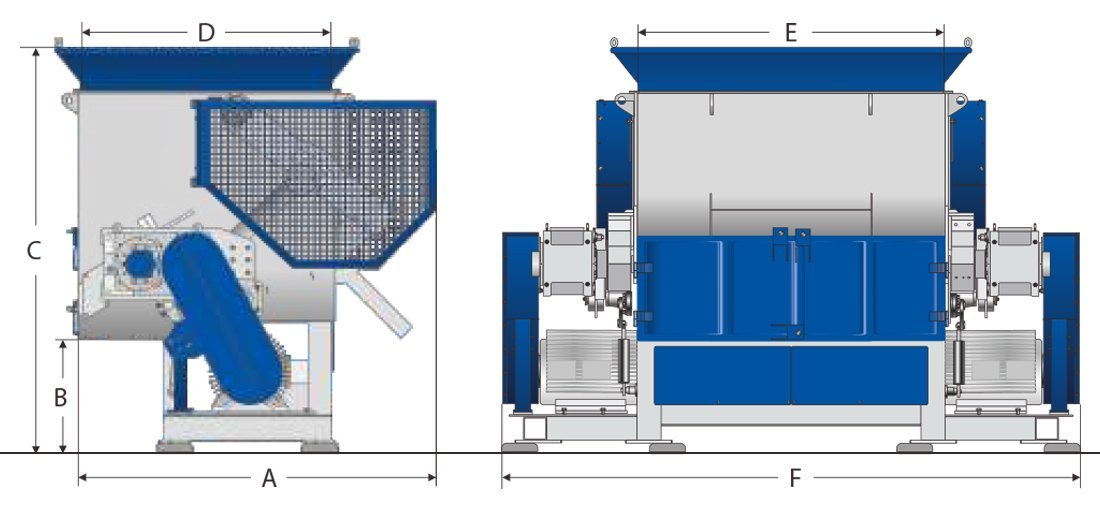

| A (mm) | 2085 | 2300 | 2300 | 2300 | 2300 |

| B (mm) | 625 | 725 | 725 | 725 | 725 |

| C (mm) | 2435 | 2600 | 2600 | 2600 | 2600 |

| D (mm) | 1360 | 1590 | 1590 | 1590 | 1590 |

| E (mm) | 840 | 840 | 1120 | 1400 | 1960 |

| F (mm) | 1940 | 1985 | 2265 | 2590 | 3710 |

More information about this model can be found on

The values of the individual machines may differ from the values in the tables due to modifications.

The correct values are available from your contact.

Do you have any questions?

Do you have questions about this machine? Can not find something?

Feel free to contact us. We’re here to help.