ZBS

Affordable shredder for lumps & purgings

- Affordable solution for small lumps

- Simple upgrade for existing granulation system

- Easy to move and place

- tangential infeed avoids the need for a hydraulic pusher

- Small footprint

- Low energty consumption

Overview

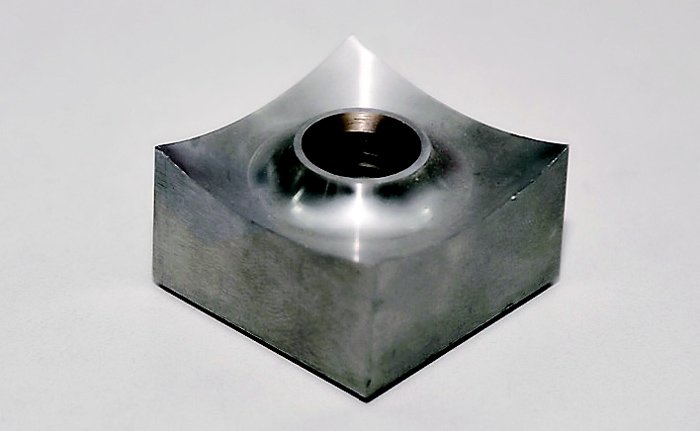

The shredders use concave ground square knives, producing high quality output. The cutters can be turned after a side is worn out.

All ZERMA shredders are equipped with our E-style flat rotor. The knives are fixed in special knife holders fitted in machined pockets.

The ZBS shredders feature an aggressive tangential infeed for easy feeding without the need for a hydraulic system. Lumps of up to 400 mm diameter can be processed easily in this machine series.

General Description

The ZBS series shredders are single shaft shredders with tangential infeed thus eliminating the need for a hydraulic feeding system.

The compact and manoeuvrable design combined with the ‘plug and play’ controls give this machine total flexibility and ease of use.

Like the bigger brothers in the ZS series, the ZBS are equipped with outboard bearings, 310 mm diameter flat E rotors with 600 mm or 850 mm width , driven by an oversized geared motor, and incorporate the proven ZERMA knife holder and knife design.

The user friendly design allows for simple and efficient cleaning and maintenance.

The low rotor speed of 60 rpm combined with the compact design of the ZBS shredders makes it possible to shred lumps at a relatively low noise level.

The machines can be fed manually or by conveyor. Material discharge can be done via conveyor or into a drop box.

Applications

The ZBS shredders have been designed for in house recycling of small lumps and purges from injection and blow molding processes.

The typical input materials are small and medium sized cakes such as head waste. The material can be shred to reduce the volume or processed further in a granulator to be re introduced into the production process immediately.

The machine also can be used to destroy sensitive products or to recycle small batches of low volume products to avoid contamination of the main product line.

Specifications

| Typ | 600 | 850 |

|---|---|---|

| Rotor diameter (mm) | 310 | 310 |

| Rotor width (mm) | 560 | 840 |

| Rotor speed (rpm) | 61 | 61 |

| Drive capacity (kW) | 11 | 18.5 |

| Rotor knifes (pcs) | 26 | 40 |

| Stator blades (rows) | 1 | 1 |

| Screen size (mm) | > 16 | > 16 |

| Effective working area (mm) | 490 x 550 | 490 x 830 |

| Weight approx. (kg) | 1400 | 1500 |

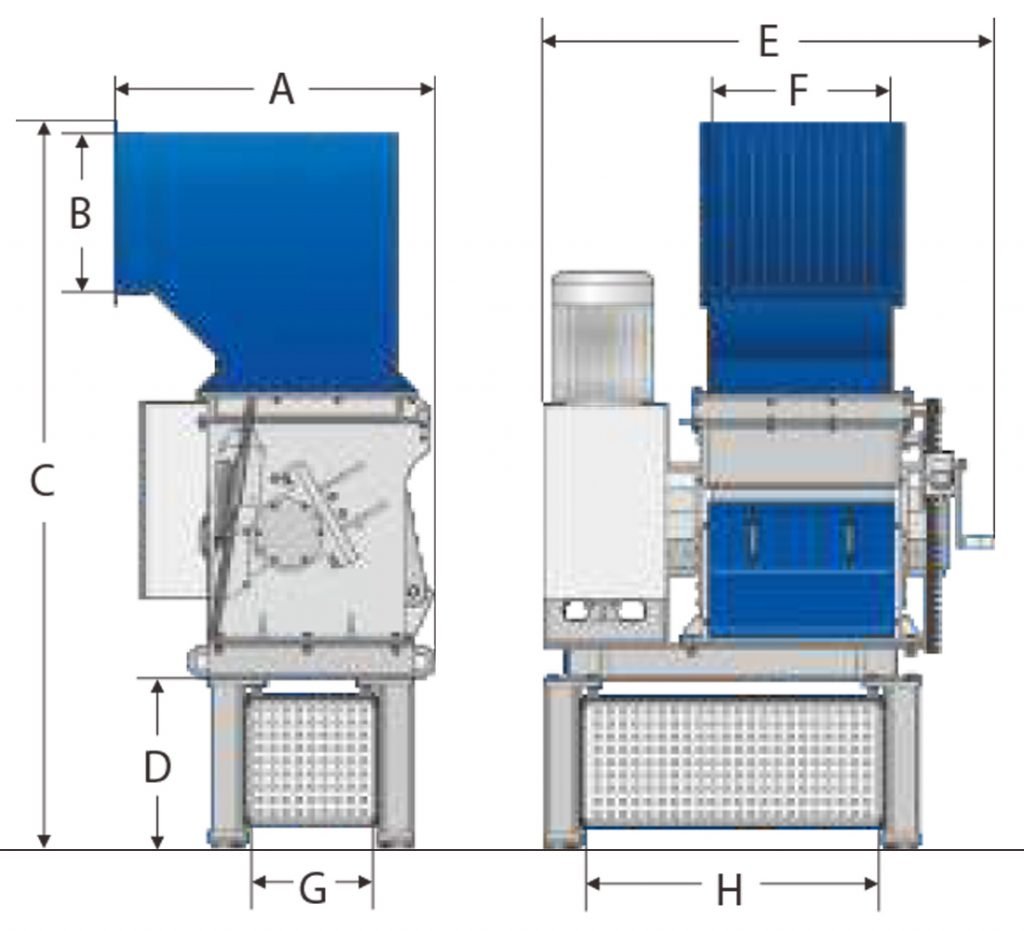

| A (mm) | 995 | 1045 |

| B (mm) | 490 | 490 |

| C (mm) | 2255 | 2255 |

| D (mm) | 525 | 525 |

| E (mm) | 1400 | 2080 |

| F (mm) | 550 | 830 |

| G (mm) | 420 | 470 |

| H (mm) | 950 | 1200 |

More information about this model can be found on

The values of the individual machines may differ from the values in the tables due to modifications.

The correct values are available from your contact.

Do you have any questions?

Do you have questions about this machine? Can not find something?

Feel free to contact us. We’re here to help.