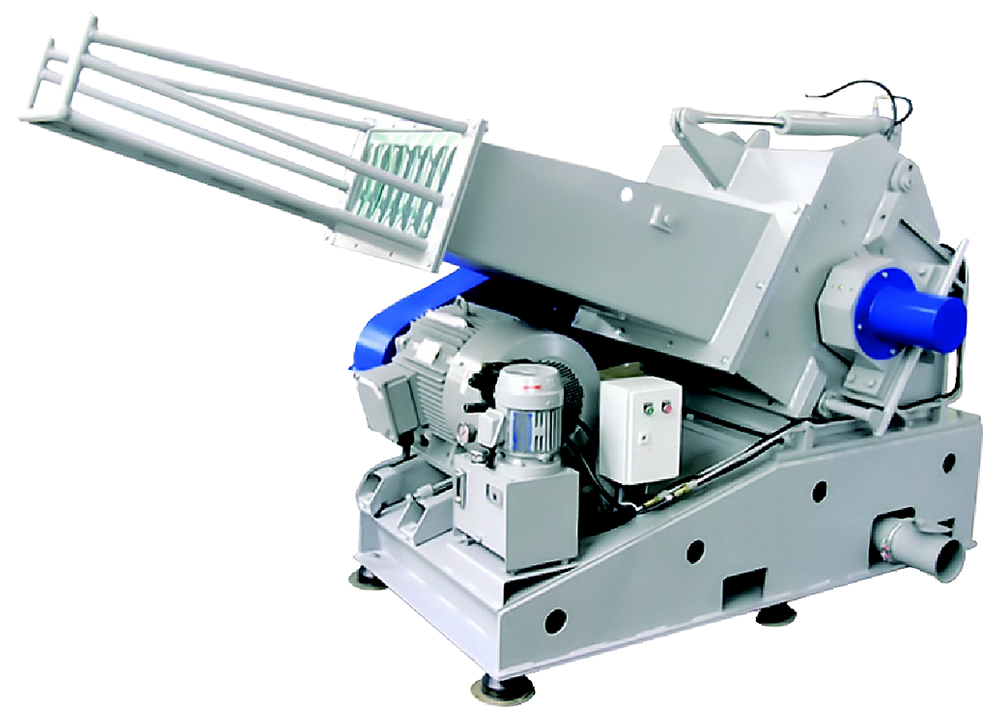

GSP

Granulator for tubes and pipes

- Knives are adjusted outside of the machine

- Specially developed deflector wedge

- Wide choice of rotors

- Well thought out housing design

- Strong Welded Steel construction

- Oversized outboard bearings

Overview

Rotor and stator knives are pre-set outside the machine prior to installation in a supplied fixture. This makes awkward adjustment inside the machine unnecessary.

The specially angled rotor automatically pulls the fed pipes or profiles into the cutting chamber, this design also regulates the amount of material.

General Description

The Pipe and Profile Granulators of the GSP series are available in rotor widths of up to 1400mm and diameters ranging from 560 to 700 mm. The completely welded heavy steel cutting chamber is angled and fitted with an extended hopper to allow easy feeding of parts.

The standard V-cut creates a high quality regrind with a very low percentage of fines in the output material. Other standard features include an hydraulically opened hopper for outboard bearings reducing the risk of contamination.

Applications

Conventional granulators have substantial problems handling long pipes and profiles.

To feed large and bulky parts in most cases cavities or platforms are needed. Therefore Zerma developed the GSP range.

Thanks to the almost level feeding hopper, long pieces can be fed easily.

While the machine is operating there is no risk of blocking, in case of congestion no more material will be accepted by the machine until the grinding chamber is empty and the machine will accept material again, and work continues.

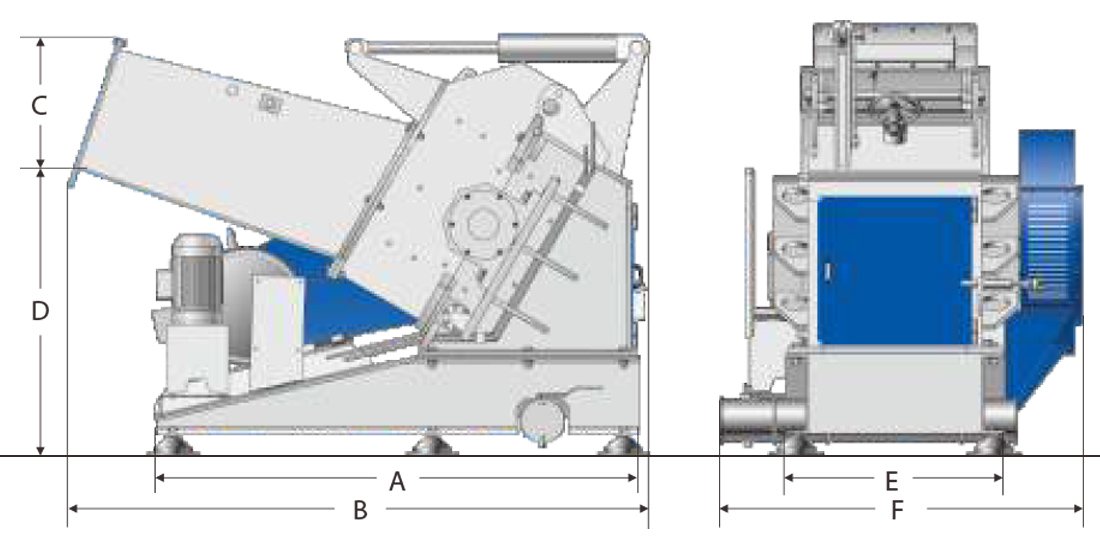

Specifications

| Typ | 600/500 | 560/700 | 560/1000 | 700/1400 |

|---|---|---|---|---|

| Rotor diameter (mm) | 600 | 560 | 560 | 700 |

| Rotor width (mm) | 500 | 700 | 1000 | 1400 |

| Drive capacity (kW) | 45 | 55 | 75 | 90 |

| Rotor knifes (rows) | 5 | 5/7 | 5/7 | 5/7 |

| Stator blades (rows) | 2 | 2 | 2 | 2 |

| Screen size (mm) | > 8 | > 8 | > 8 | > 8 |

| Effective working area (mm) | 440 x 530 | 290 x 740 | 290 x 1010 | 320 x 1440 |

| Weight approx. (kg) | 4000 | 5000 | 6400 | 9000 |

| A (mm) | 1940 | 2290 | 2290 | 2420 |

| B (mm) | 2245 | 2400 | 2450 | 2580 |

| C (mm) | 440 | 220 | 220 | 300 |

| D (mm) | 1040 | 1250 | 1250 | 1255 |

| E (mm) | 940 | 1170 | 1380 | 1840 |

| F (mm) | 1350 | 1785 | 2060 | 2400 |

More information about this model can be found on

The values of the individual machines may differ from the values in the tables due to modifications.

The correct values are available from your contact.

Do you have any questions?

Do you have questions about this machine? Can not find something?

Feel free to contact us. We’re here to help.